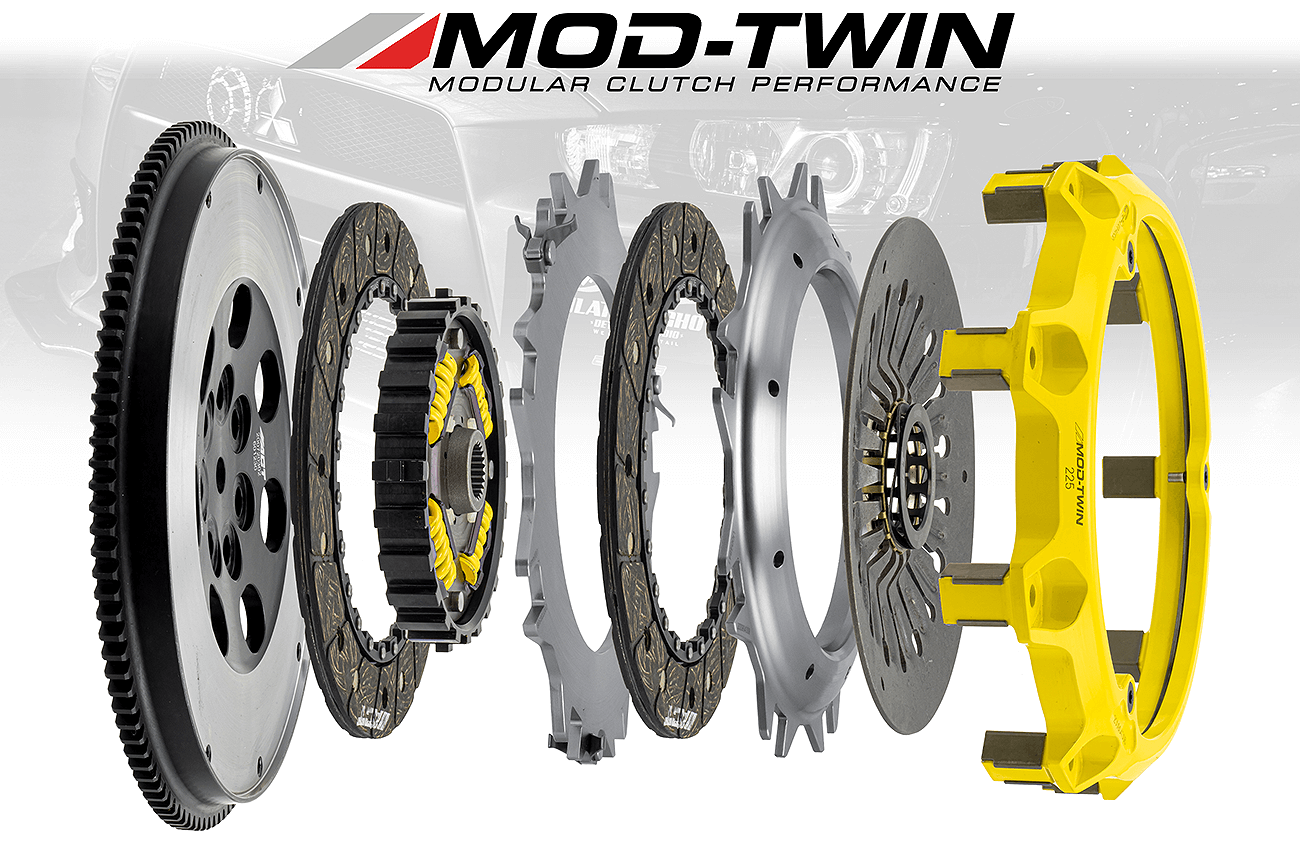

Friction Plates

Uniformly load the Mono-Drive Hub during engagement. Steel backed organic for street applications and smooth engagement, ceramic puck type for racing applications, increased heat capacity.

Friction Plates

Uniformly load the Mono-Drive Hub during engagement. Steel backed organic for street applications and smooth engagement, ceramic puck type for racing applications, increased heat capacity.

Mono-Drive Hub

Transfers the power from the friction plates to the input shaft. You can choose a robust spring center for longer spline life, less gear noise and cushion engagement or choose rigid design for faster shifts.

Centering-Springs

Stainless Spring Steel assures cleaner, quicker shifting by pushing the surfaces apart during disengagement and provides smoother, more predictable clutch engagement.

Floater Plate

Chromoly steel machined to exact specifications. High strength steel construction for transmitting high torque levels, while also remaining flat under thermal stress to keep shifts clean and quick.

Forged Aluminum Cover

Forged Aluminum, integrated nine post design engineered strong, light, and rigid using finite element analysis (FEA).

Anti-Rotation Pins

Prevents undue wear from the diaphragm “walking” in extreme output applications.

Wear Plates

Hardened stainless steel on each post to prevent damage from torsional impacts.

Diaphragm

Optimized design using ACT’s exclusive four stage heat treating process. Provides a consistent light pedal feel.

Mono-Loc

A must-have to assure reliable attachment of the release bearing. This solves the OE wedge collar woes.

Streetlite Flywheel

Chromoly steel, engineered using finite element analysis (FEA), reduced weight with enough material to absorb heat, precision balanced, induction hardened ring gear teeth integral to the flywheel. This one-piece design is stronger and more durable than billet steel, aluminum, or cast iron.

Pressure Plate Face

Precision machined chromoly steel to ensure strength and long life with ample material to dissipate heat.

Friction Plates

Uniformly load the Mono-Drive Hub during engagement. Steel backed organic for street applications and smooth engagement, ceramic puck type for racing applications, increased heat capacity.

Floater Plate

Chromoly steel machined to exact specifications. High strength steel construction for transmitting high torque levels, while also remaining flat under thermal stress to keep shifts clean and quick.

Wear Plates

Hardened stainless steel on each post to prevent damage from torsional impacts.

Diaphragm

Optimized design using ACT’s exclusive four stage heat treating process. Provides a consistent light pedal feel.

Mono-Drive Hub

Transfers the power from the friction plates to the input shaft. You can choose a robust spring center for longer spline life, less gear noise and cushion engagement or choose rigid design for faster shifts.

Forged Aluminum Cover

Forged Aluminum, integrated nine post design engineered strong, light, and rigid using finite element analysis (FEA).

Streetlite Flywheel

Chromoly steel, engineered using finite element analysis (FEA), reduced weight with enough material to absorb heat, precision balanced, induction hardened ring gear teeth integral to the flywheel. This one-piece design is stronger and more durable than billet steel, aluminum, or cast iron.

Centering-Springs

Stainless Spring Steel assures cleaner, quicker shifting by pushing the surfaces apart during disengagement and provides smoother, more predictable clutch engagement.

Anti-Rotation Pins

Prevents undue wear from the diaphragm “walking” in extreme output applications.

Mono-Loc

A must-have to assure reliable attachment of the release bearing. This solves the OE wedge collar woes.

Pressure Plate Face

Precision machined chromoly steel to ensure strength and long life with ample material to dissipate heat.

Why a Mod-Twin?

Mitsubishi Evo’s and Subaru STi’s have turbo four-cylinder engines that make big power. The turbo four-cylinder engines have a lot of torsional vibration and they are notorious for being hard on clutches (specifically stripping out the splines in the hubs). The problem? It was too difficult to get two spring centered hubs in such a small space to adequately reduce torsional vibrations. We created a clutch that is completely modular, and both friction plates mount to one Mono-Drive Hub. Problem Solved! Choose either organic or six puck style friction materials, a spring center or solid center Mono-Drive Hub. For race options we offer our Xtreme or MAXX Xtreme kits. This clutch is completely rebuildable and all the wear surfaces are hardened. What we keep seeing out in the marketplace, was either race clutches adapted for street use or clutches with significant tradeoffs such as:

- Short clutch life - Splines wear out, material wears out.

- Noisy or harsh engaging.

- Low heat capacity.

- Slow shifting - hard on transmissions.

- Pull to push conversions that do not perform, are complicated, or use expensive parts.

THE ACT Difference

We refused to offer a twin disc without having something more to offer. The performance requirements are obvious, and we know how to achieve them:

- Must hold big power.

- Must have good heat capacity.

- Strong and durable.

- Clean shifting.

In addition:

- Have great pedal feel and engagement characteristics.

- It needs to last! Extended friction, and spline life.

- Not be noisy.

How? We had four must-have design goals:

- It needs to be pull type.

- Use only one hub.

- Be able to offer sprung center or solid.

- Choice of different friction materials with ability to expand into other materials.

WHICH MOD-TWIN DO I NEED?

At ACT we do not call out Stages, as this can be extremely subjective. What is Stage 2 to some may be Stage 3 to someone else etc. Therefore, at ACT we rate our clutches simply by the torque capacity at the crank. At the end of the day, that is all your clutch cares about. Here's how you choose:

- Choose the Kit for your driving needs. For Street we have our Heavy Duty Kits which feature full face organic discs. For Race we have Heavy Duty, Xtreme and Maxx Xtreme Kits which feature six-puck cerametallic discs.

- Choose a Kit with a Spring-Centered Hub or a Rigid Solid Hub. Here are the differences:

- The Spring-Centered Kits’ main purpose is to provide extended life for the splines of the Hub versus a Rigid Kit. Our Heavy Duty Springs dampen (reduce) the torsional vibrations at the input shaft. The torsional vibration that these cars are known for greatly reduces the life of the splines on the hub. In addition, this kit will operate quieter and provide smooth shifting.

- The Rigid Kit’s main purpose is to provide race-proven performance with street manageability. The two major tradeoffs versus the Spring-Centered Kit are that a Rigid Kits’ hub life will be reduced as greater spline wear is expected and it has increased gear noise (will be louder). Unlike the Spring-Centered Kit, a Rigid Kit has a solid hub which does not contain Springs. The hub is lighter which results in an improved throttle response. Engagement is quick, smooth, and precise. It has the lowest inertia for fastest shifts and provides less stress on synchronizers.

- Look up the Torque capacity that we list for the kit. Choose one in the range of the torque you will be making at the crank.

It's that simple.